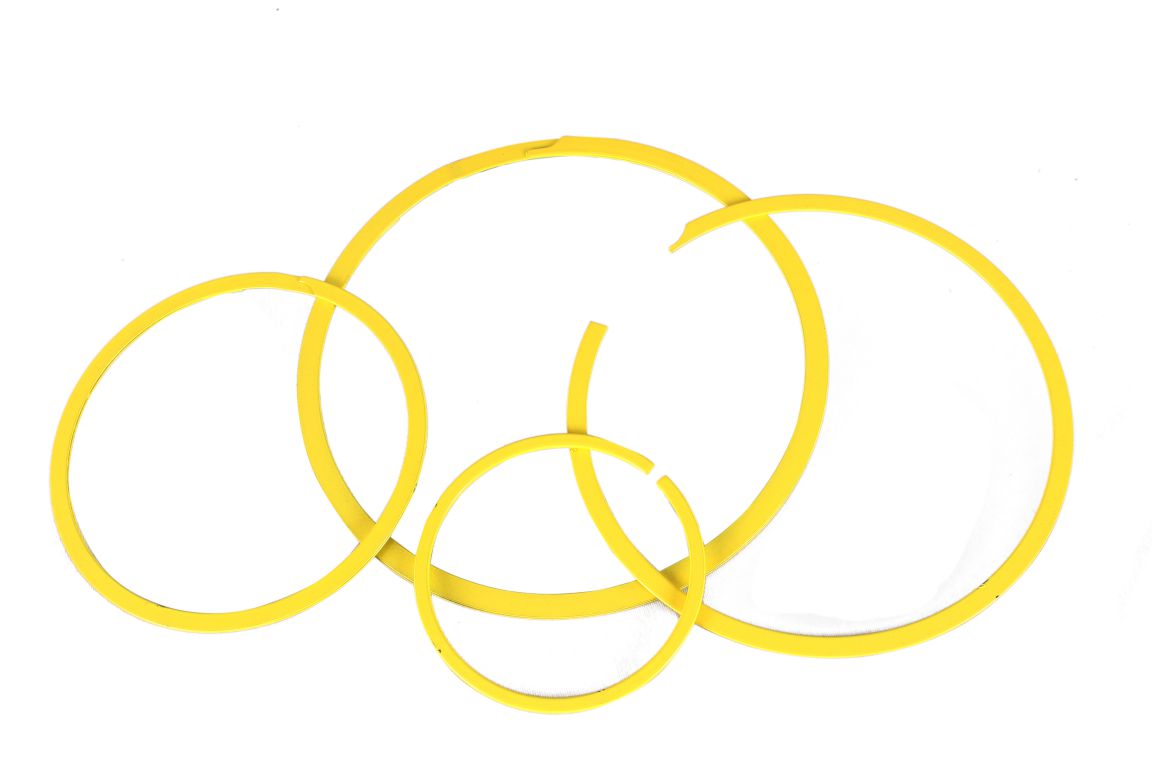

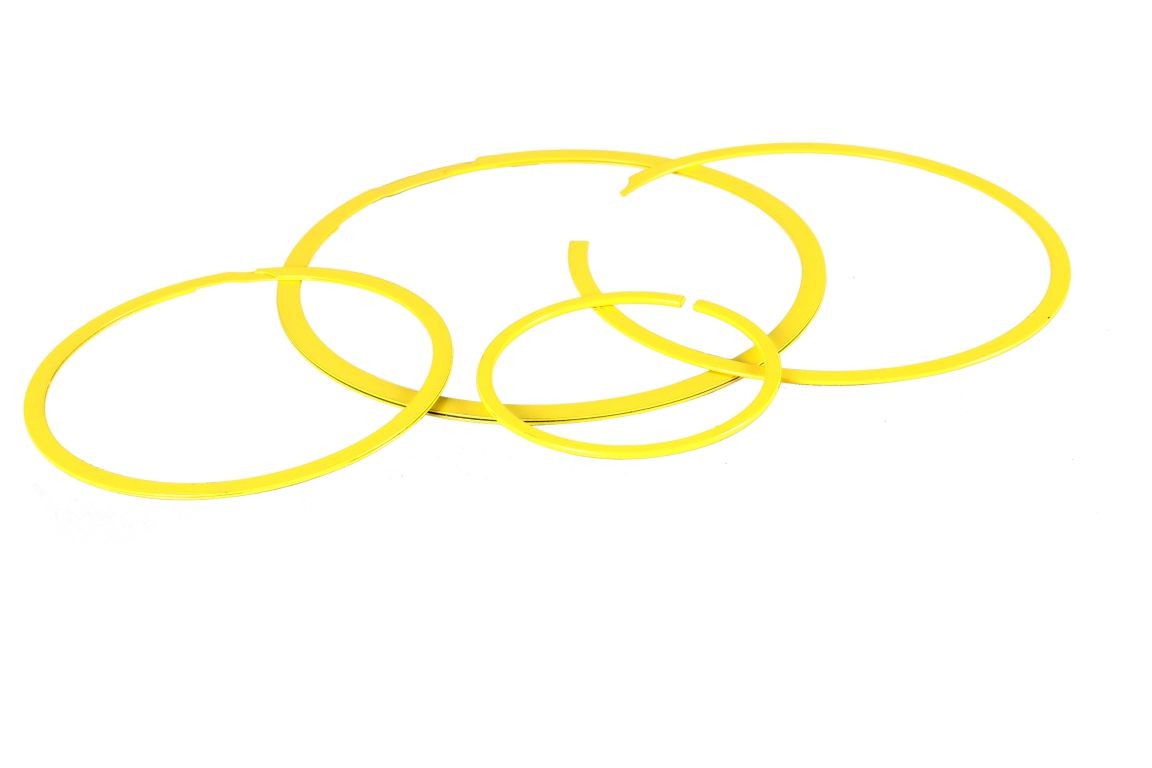

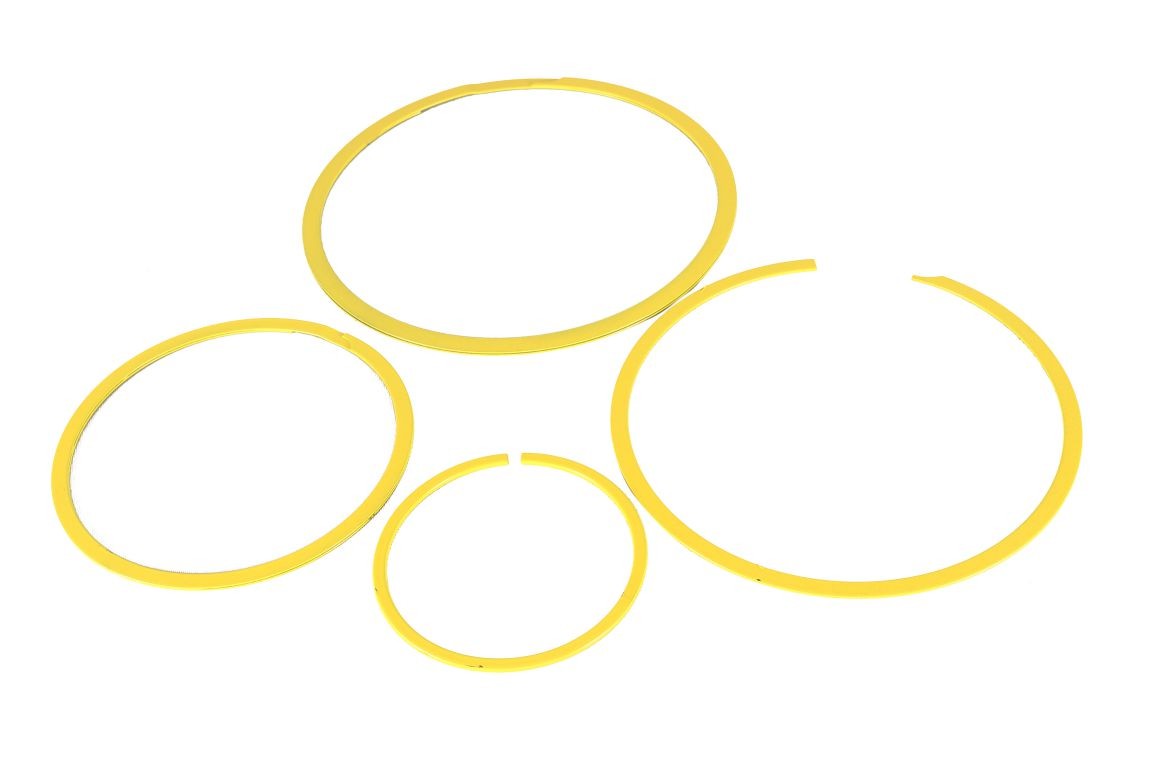

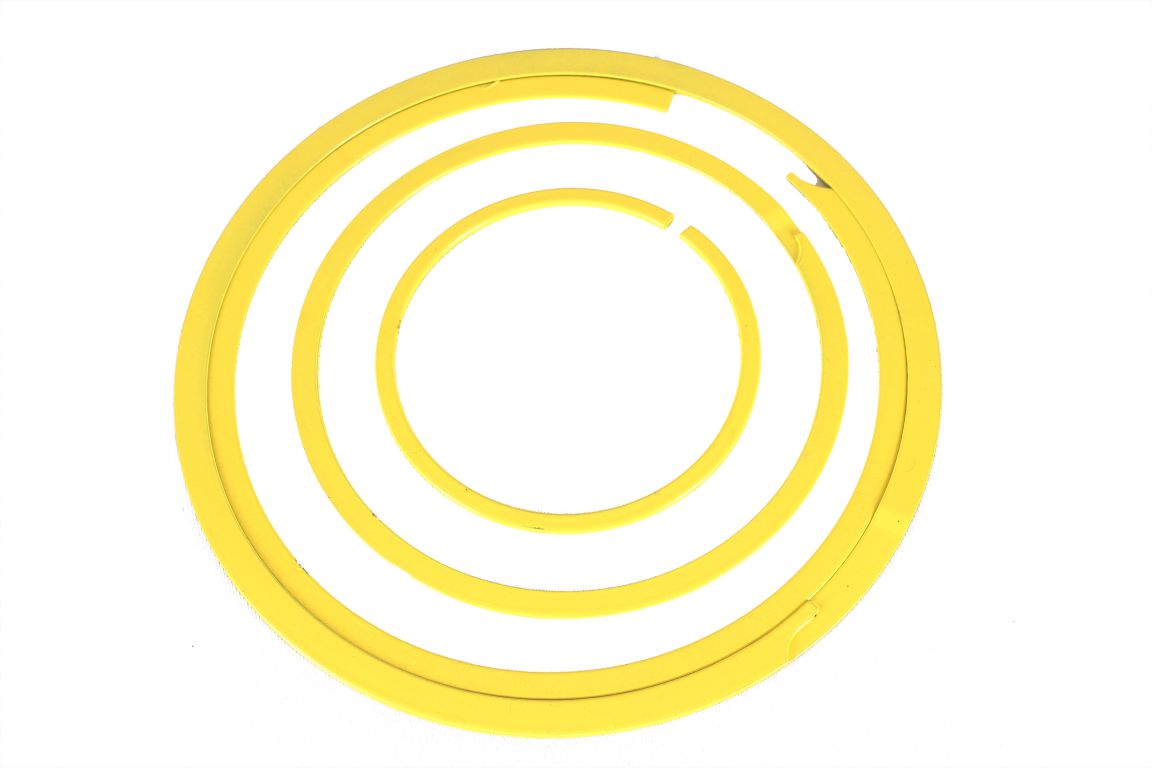

Retaining Rings

Retaining Rings is often an alternative means of sealing components in assemblies from contamination.

“We at Accurate Springs have mastered the art of manufacturing Retaining Rings.”

- Since they are produced from metal {not rubber, or other nonmetallic material} retaining rings can often withstand higher temperature and more corrosive environments and other more extreme conditions than common O-Rings or conventional rubber seals. This is the primary reason why design engineers prefer retaining rings in many applications.

- Retaining rings offer higher clamping force when installing in the bore or on the shaft and are suited for higher operating speeds having 3600 [no axle gap} contact. One typical application is where a high amount of dirt and dust are present and the ring sets provide the necessary seal against contamination from outside elements.

- Retaining rings are also used to protect contacting radial seals, rubber seals, o-rings and other oil seals.

- The retaining ring can be manufactured from spring steel flat wires and stainless steel flat wire. Many years of experience in making retaining rings have helped accurate springs to become a reliable supplier of quality retaining rings.