MANUFACTURING

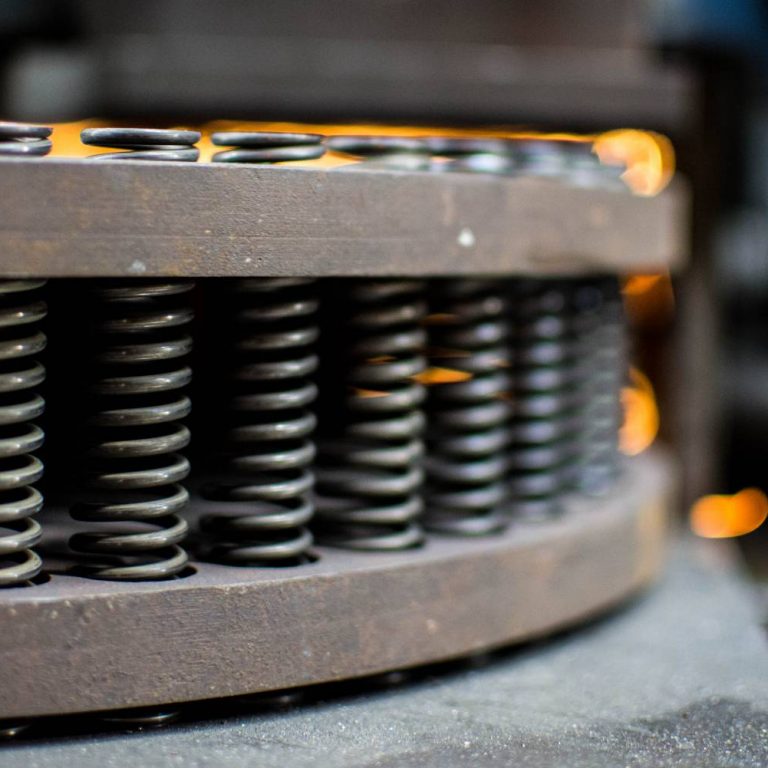

At Accurate, we manufacture over 5,000 variants of springs, ranging from 0.1mm to 12mm thickness, which finds application in almost every sector, from the manufacturing of an electrical switch to an aircraft.

MANUFACTURING PROCESS

We are spread over an area of 15,000 sq. ft. in Mumbai. This vast expanse of land has made it possible for us to house superior technology for the manufacturing processes.

- Our Manufacturing unit is dedicated to the construction of high-quality springs to meet customer requirements.

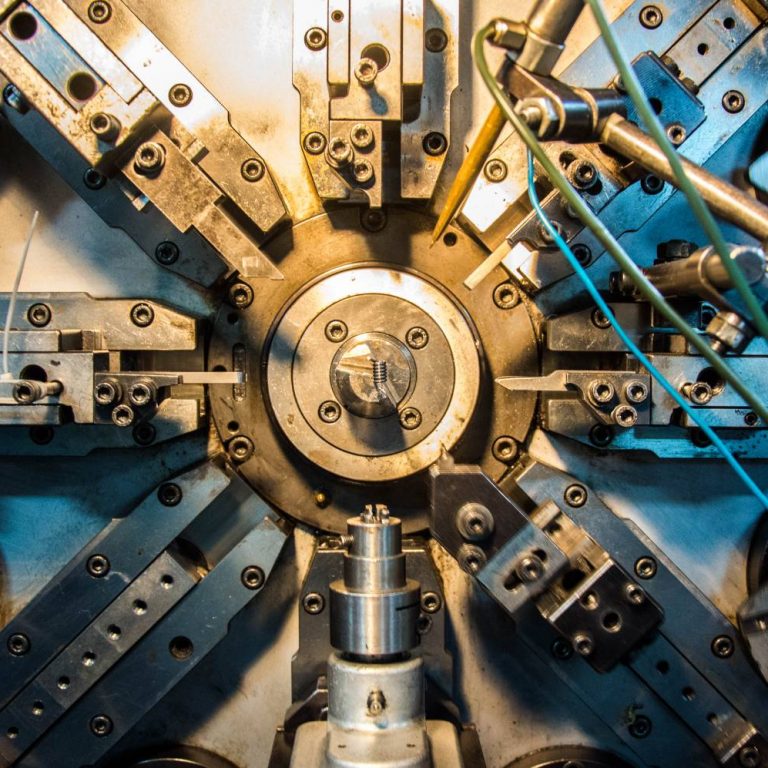

- We take pride in our large fleet of fully automatic CNC (Computerized Numeric Control) machines which includes CNC compression springs coiling machine, CNC copper coils making machine, Tension springs making CNC machine, Torsion springs making CNC machine, etc.

- The springs are made in accordance with the requirements of the client and can be customized to specified strengths to suit different specifications.

- The size and shape of the material are chosen to suit the necessities of the buyer. The length of the spring, the inside and outside diameter, the load applied, purpose and placement, shape and style of the ends need to be mentioned for manufacturing.

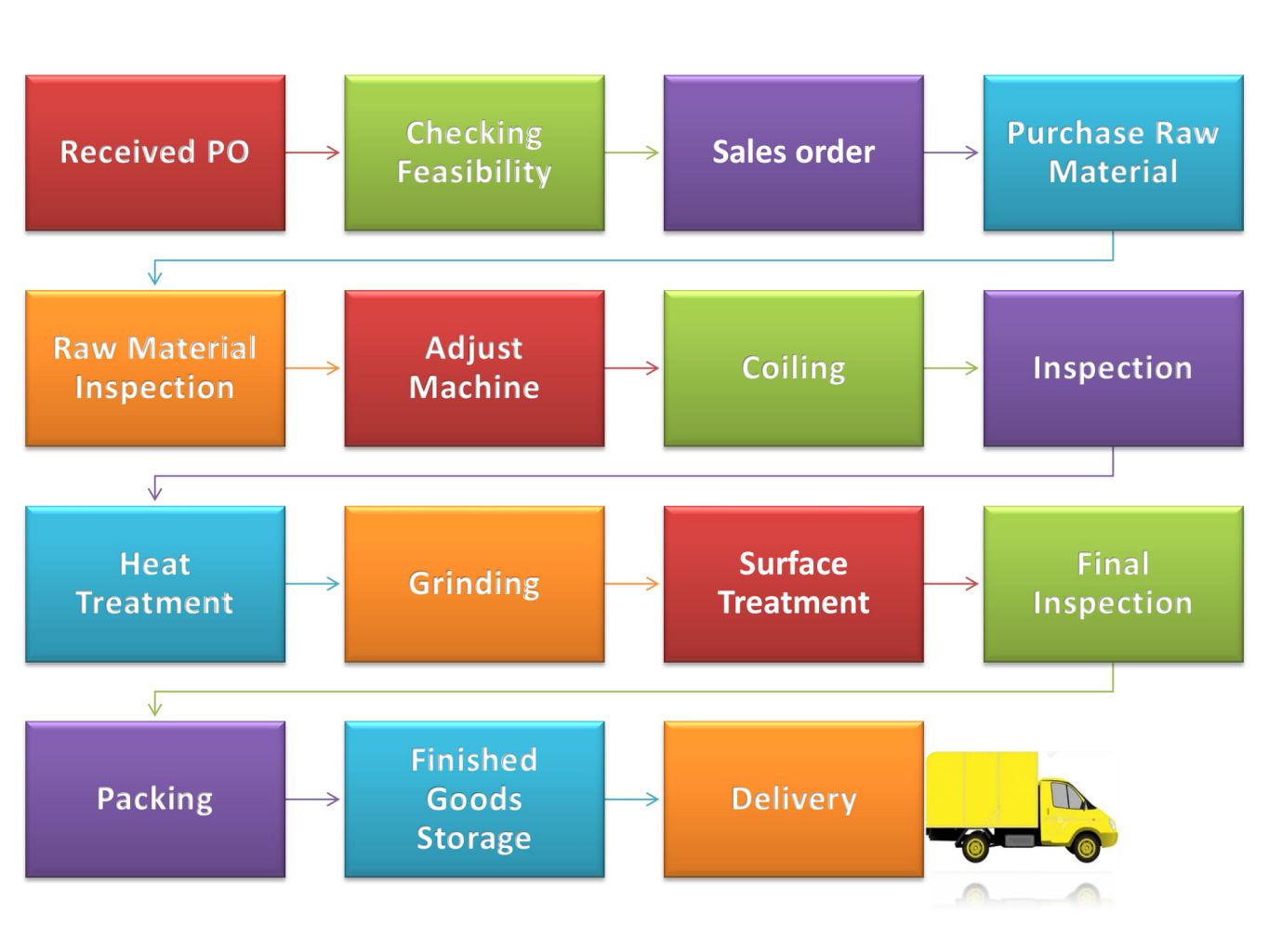

- Before commencing the manufacturing process it is important to check the practicality of the specifications of the anticipated spring. We are one of the rare companies to have invested in the software from the Institute of Spring Technology, the UK for a reliable design.

- We staunchly believe that the machines must be operated for manufacturing once a concrete, infallible and validated design is prepared.

- The CNC machines are used to make these. The machine helps operations on x, y, and z-axis with the help of a programmable logic controller. The technician does the initial set-up of the machine to manufacture the desired springs.

- These CNC machines work on every detail involved in the manufacturing of the springs once the values are fed in. Post formatting, the preferred raw materials are fed into these machines. These machines work on the coiling, bends, loops, hooks, wire form, radius and the shaping of the ends.

- We are well equipped with a special machine to sort through the compression springs automatically; the machine resets if it encounters a defective spring, ensuring the removal of faulty products.

- Double torsion springs, extension with square or complicated hook forms springs, etc. can also be manufactured easily. We are equipped with elaborate machinery for manufacturing a variety of torsion springs as well.

- The spring angle is checked on the machine itself. The hi-tech machinery has assisted us to achieve a high degree of reduction in human errors in secondary operations.

- After the manufacturing, the springs undergo a process of stress relieving through heat treatments. The intensity of heat applied varies in accordance with the type of spring produced.

- They are placed on the conveyor furnace to undergo this step. The strength of the spring is improved through this method of hardening. Direct Quenching is an extended process to ensure the precision and accuracy of the manufactured springs.

- The spring undergoes tampering to ensure that the mass-produced goods have the same physical attributes. Spring Grinding is done if they need to stand upright. It helps in checking the quality of squareness of the ends.

- The next step is shot peening to remove the residual stress in the springs. This process strengthens the steel to resist cracking during its lifetime of repeated flexings.

- After all the springs are ready, the final step of spring plating and coating is performed to ensure a clean finish.

- Over the last decade, our talented team of engineers has successfully provided fast, precise and economical solutions to custom manufacturing demands.