RAW MATERIALS

The raw materials used in the manufacturing of a product depend on two factors: the sustainability and the application. We believe in using materials that reduce environmental threat and meet the criteria of the customers.

We, at Accurate, ensure that above-mentioned materials used in the manufacturing of various products are of IS Standard.

The constituent materials for spring manufacturing can be broadly categorized into 5 groups – high carbon spring steel, alloy spring steel, stainless steel, phosphor bronze, and copper base alloys.

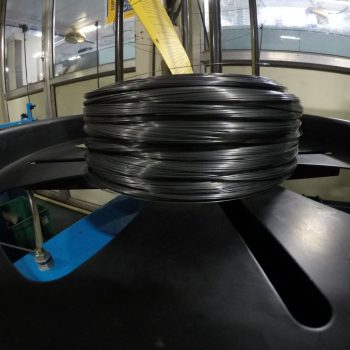

Spring steel wire (IS 4454)

There are basic 4 grades given to steel wire used for making springs.

- Grade 2 &3 are most commonly used in India for making springs.

- Grade 4 has very high accuracy in physical &chemical parameters.

Valve spring wires

- Automotive applications for engine valves, pump, etc. where high fatigue life is required.

Alloyed steel wire-(Silicon Chrome)

- Used for springs which are subject to “high static and dynamic loading” Raw Materials

Stainless steel wire-AISI 302/304/

- Have less magnetic properties

- Resistant to corrosion

- High elasticity

- Resistant to heat

- Used in electrical and related industries

Copper base alloy – used in high electrical & thermal conductivity

- Non-magnetic

- Good atmosphere resistance is required

- Phosphor bronze wires due to high tensile strength are most widely used copper alloys for manufacturing springs

- Resistant to heat

- The bare copper wire is coated with polyester enamel to make it non-conductive